HKUST Researchers Develop the World’s Strongest Polymer Nanomembrane

The Importance of Sustainable Polymer Materials

Polymers are a fundamental component of modern life, used in a wide range of applications from packaging and textiles to medical devices and construction materials. The importance of polymers cannot be overstated, as they provide numerous benefits such as durability, flexibility, and resistance to chemicals and heat. However, the plastics industry has faced growing criticism in recent years due to its significant contribution to environmental pollution and waste management issues. As a result, there is an increasing emphasis on sustainability in the plastics industry, driven by evolving stakeholder expectations and environmental awareness. This shift towards sustainability is crucial for the long-term viability of the plastics industry, as it requires the development of innovative and eco-friendly strongest polymer materials that minimize environmental impact while maintaining performance and functionality. The development of strongest polymer materials is a key focus area for researchers and industry players alike, as they strive to create more sustainable and high-performance polymer solutions.

Identifying the Strongest Polymer Materials

The strength of a polymer material is determined by a combination of factors, including its molecular structure, intermolecular forces, and the orientation and alignment of the polymer chains. Strongest polymer materials are characterized by their ability to withstand high levels of stress and strain without compromising their structural integrity.

One of the key criteria for evaluating polymer strength is tensile strength, which measures the maximum stress a material can withstand before breaking. Polymers with high tensile strength, such as ultra-high molecular weight polyethylene (UHMWPE), are particularly desirable for applications where durability and load-bearing capacity are crucial.

In addition to tensile strength, other important factors that contribute to a polymer's overall strength include its resistance to compression, shear, and impact. The arrangement and interactions of the polymer chains, as well as the presence of cross-links and crystalline regions, can significantly influence these mechanical properties.

By understanding the underlying principles that govern polymer strength, researchers and engineers can design and develop innovative strongest polymer materials that push the boundaries of what is possible in terms of performance and sustainability. This knowledge is essential for creating the next generation of high-performance, eco-friendly polymer solutions.

Emerging and Innovative Strongest Polymer Materials

Researchers are continuously pushing the boundaries of polymer technology, exploring new ways to create even stronger and more versatile materials. Two key areas of innovation in strongest polymer development include graphene-reinforced polymers and nanocomposite polymers.

Graphene-Reinforced Polymers: Graphene, a single-atom-thick sheet of carbon, is renowned for its exceptional strength and stiffness. By incorporating graphene into polymer matrices, researchers have been able to create composite materials with significantly enhanced mechanical properties. These graphene-reinforced polymers have shown great potential for applications in electronics, energy storage, and structural engineering.

Nanocomposite Polymers: Another approach to developing strongest polymer materials involves the incorporation of nanoparticles, such as carbon nanotubes or clay nanoplatelets, into the polymer matrix. The addition of these nanofillers can dramatically improve the strength, stiffness, and thermal stability of the polymer, opening up new possibilities for high-performance applications.

Researchers at the Hong Kong University of Science and Technology (HKUST) have made a ground-breaking contribution to the field of strongest polymer materials. They have successfully developed an ultrathin polymer nanofilm that is 25 times stronger than stainless steel of the same mass.

This revolutionary material is also highly transparent, gas-permeable, and water-proof, with adjustable porous properties, making it suitable for a wide range of applications, including wearable devices, medical protection, desalination, electronics, and solar cells.

HKUST has filed six other patents for the material's application in various areas, and the nanofilm's adjustable porous property has made it the world's most potent polymeric membrane for membrane distillation desalination.

This remarkable achievement by HKUST researchers highlights the immense potential of innovative strongest polymer materials to transform industries and pave the way for a more sustainable future.

Factors Driving the Demand for Strongest Polymer Materials

The growing demand for strongest polymer materials can be attributed to several key factors, including the need for lightweight and high-performance materials, as well as increasing sustainability and environmental considerations.

Lightweight and High-Performance Requirements: Many industries, such as aerospace, automotive, and electronics, are constantly seeking materials that can provide superior strength-to-weight ratios. Strongest polymer materials, like the ultrathin polymer nanofilm developed by HKUST researchers, offer exceptional strength and durability while being significantly lighter than traditional materials like steel. This makes them highly desirable for applications where weight reduction is crucial for improving efficiency and performance.

Sustainability and Environmental Considerations: As the world becomes more conscious of the environmental impact of various industries, there is a growing emphasis on developing sustainable and eco-friendly materials.

Strongest polymer materials, with their potential for reduced resource consumption and waste, are well-positioned to meet the increasing demand for sustainable solutions. The adjustable porous properties and gas-permeability of HKUST's polymer nanofilm, for example, make it a promising candidate for applications in water purification, energy storage, and other green technologies.

Technological Advancements and Innovation: Breakthroughs in polymer science and engineering, such as the HKUST researchers' innovative approach to manipulating the polymer chains, have enabled the development of unprecedented strongest polymer materials. These technological advancements, coupled with ongoing research and development efforts, are driving the creation of even more advanced and versatile polymer solutions that can address a wide range of industry challenges.

As the demand for lightweight, high-performance, and sustainable materials continues to grow, the importance of strongest polymer materials will only increase. The innovative work being done by researchers at HKUST and other institutions around the world is paving the way for a future where these remarkable materials play a crucial role in shaping a more sustainable and technologically advanced world.

The development of strongest polymer materials has emerged as a critical area of focus for researchers and industry players alike. These innovative polymer solutions offer a unique combination of exceptional strength, lightweight, and sustainability - properties that are in high demand across a wide range of industries.

As we look to the future, the evolution of polymer technology will undoubtedly continue to push the boundaries of what is possible, driving advancements in a wide range of industries and contributing to a more sustainable and prosperous global community.

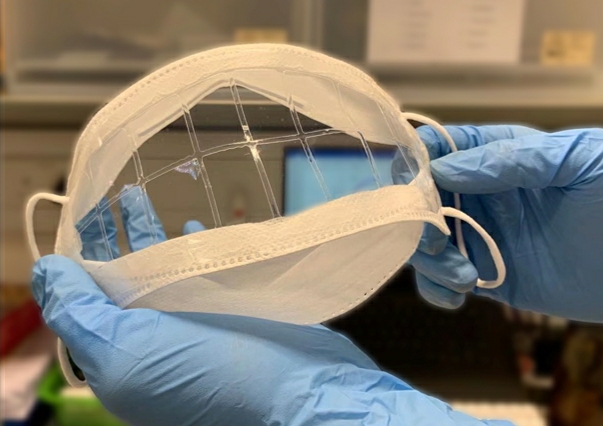

Researchers from the Hong Kong University of Science and Technology (HKUST) have developed an ultrathin polymer nanofilm, which is not only 25 times stronger1 than stainless steel with the same mass, but is also extremely transparent, gas-permeable and water-proof with adjustable porous properties, making it suitable for use as wearable devices, medical protection, desalination, electronics, solar cells and many other cutting-edge technologies.

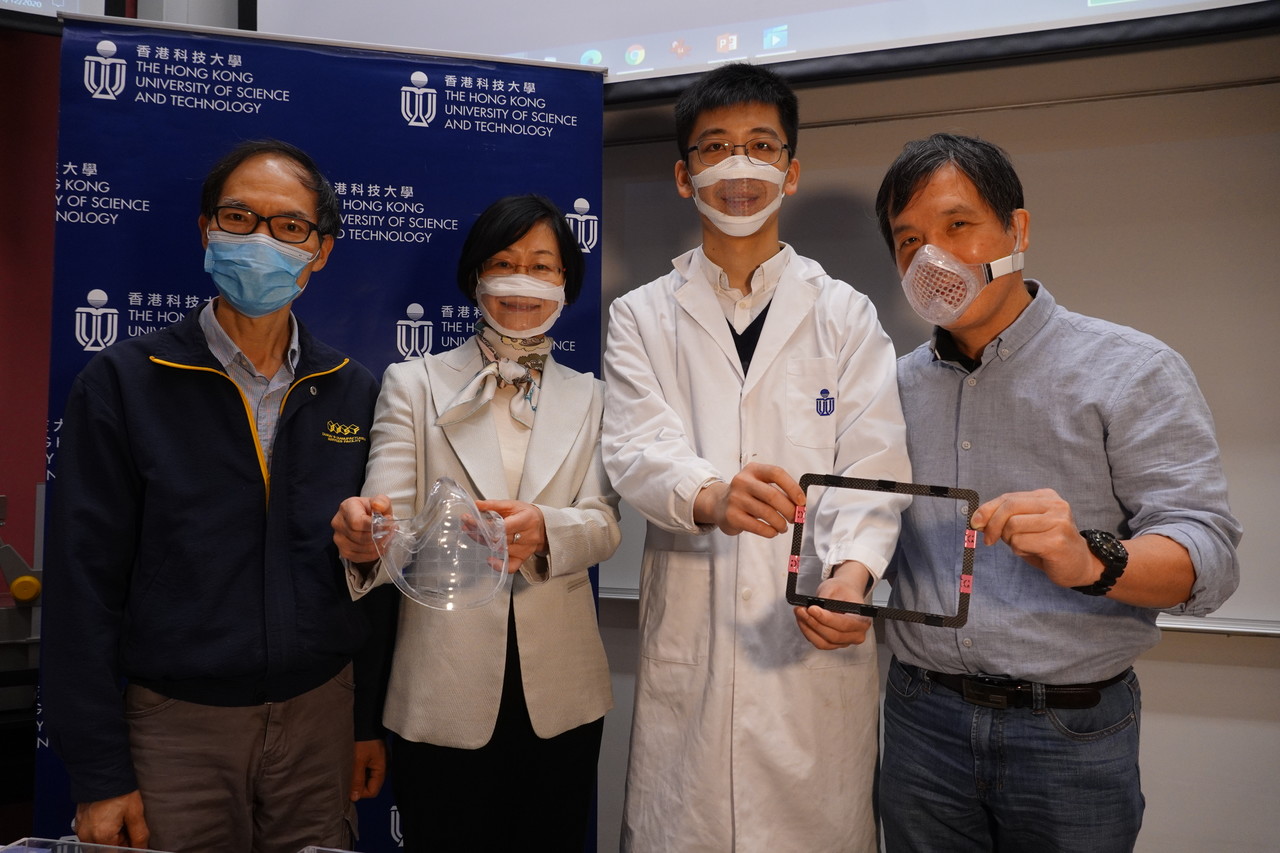

Since the onset of the Covid-19 pandemic, the team led by Prof. GAO Ping, Professor of Chemical and Biological Engineering and Acting Head of the Advanced Materials Thrust at HKUST(GZ), has been studying how to build a transparent and breathable face mask with their novel advanced material. After months of efforts the team has finally produced a prototype with a 99 per cent filtration efficiency for virus, bacteria and particulate matters under tests in line with NIOSH NaCI (N95 respirator testing standard)2 .

“This novel material has many potential, but since the pandemic struck, we focus on turning our nanofilm into a face mask that is not only transparent and breathable, but is also highly efficient against virus and bacteria, as we haven’t yet seen one in the market which bears all three properties,” said Prof. Gao. “While common opaque surgical masks can protect the wearer from infection, they are not convenient for the hearing-impaired people who need to communicate via lip reading and facial language; or teachers, child carers or performers who rely heavily on facial expressions in teaching, nurturing or performance.”

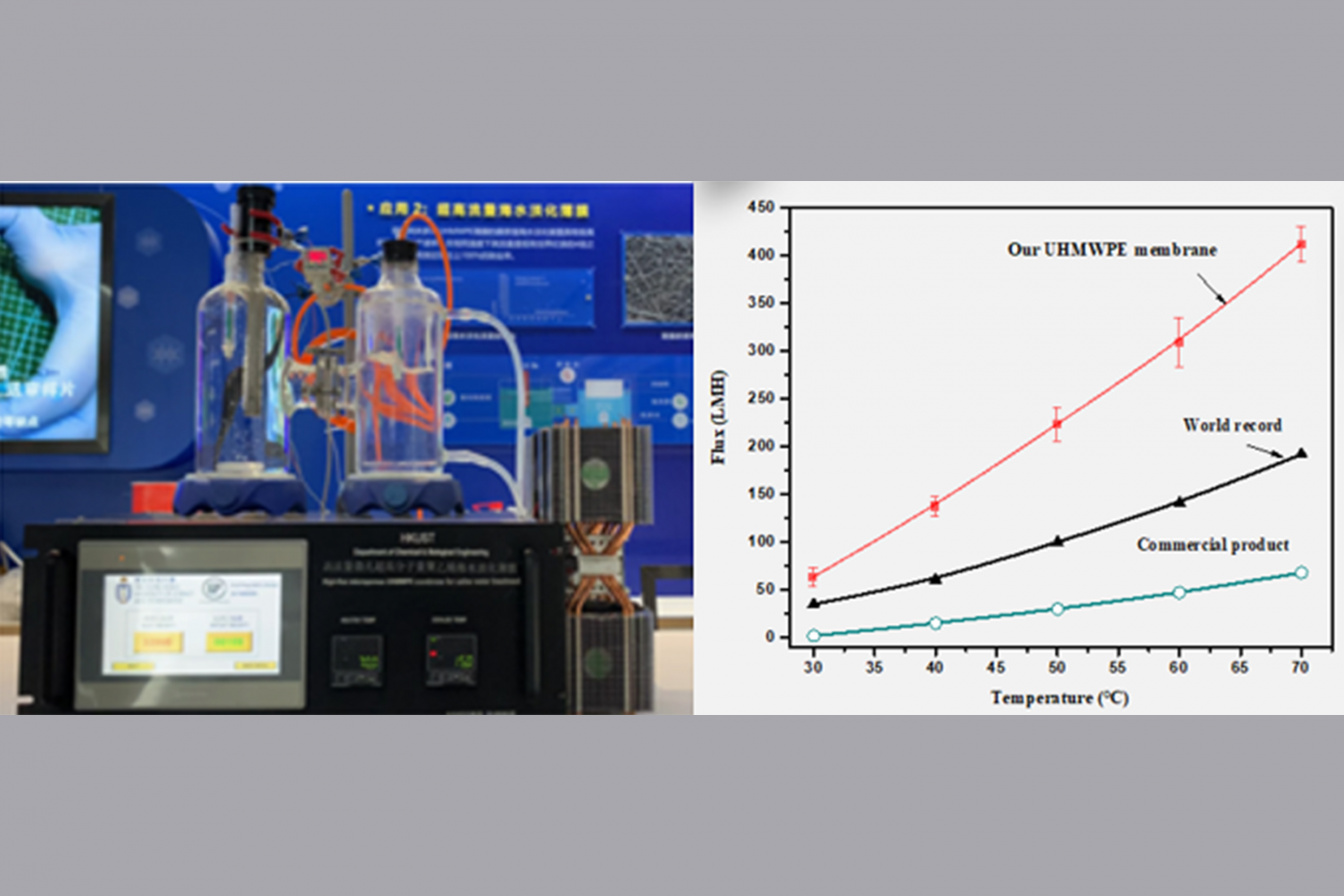

Apart from face mask, the team has also filed six other patents for the material’s application in other areas. The nanofilm’s adjustable porous property, for example, has made it the world’s most potent polymeric membrane for membrane distillation desalination so far, with an efficiency 10 times higher than existing products in the market and almost three times above world record.

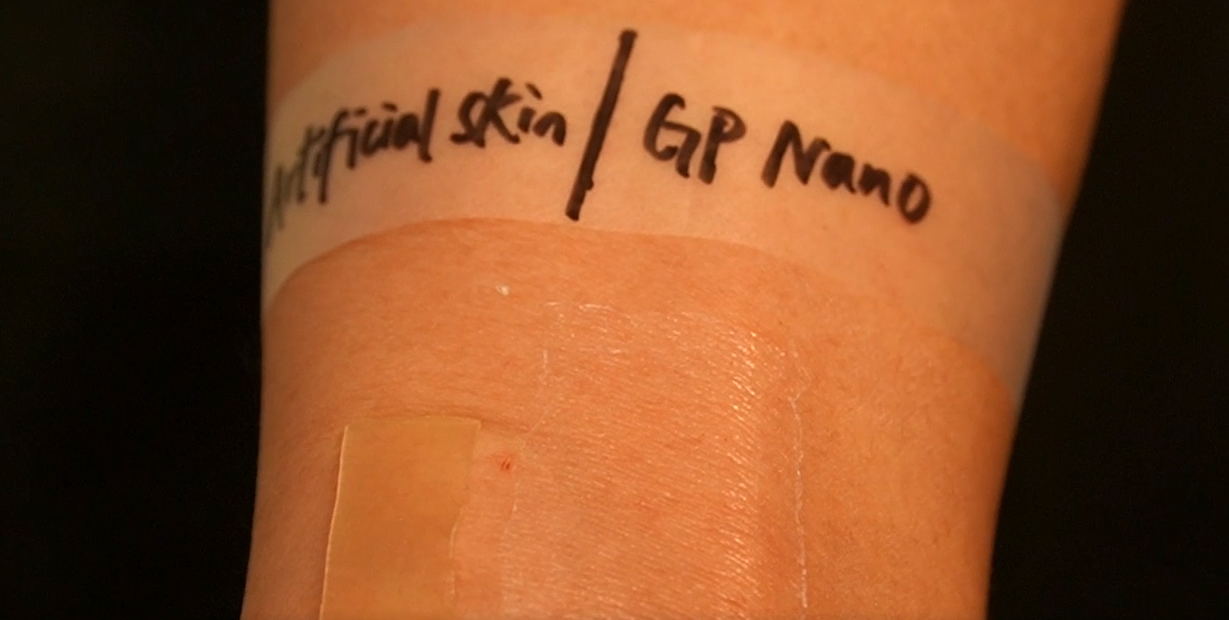

Meanwhile, its conformity, antibacterial, transparent yet strong properties has also made it an ideal material for various biomedical causes, including a new generation of wound dressing which require no daily replacement and allows direct application of medicine.

“Wound dressing made with this nanofilm is particularly useful for patients who suffer large-scale burns,” said Prof Gao. “It acts like a temporary skin to the burn victim, doctors can apply medicine directly over the film, which would filter through to the wound beneath. As the film is completely water-proof, wearers can even take a shower without fearing of wetting the wound.”

The material also makes a much better motion sensor for people, it can also be adopted for the design of robotic motions. Apart from biomedical and environmental use, the nanofilm can also be applied to electrical appliances, such as nanovibrational speaker with higher resolution of audio output or ultrathin batteries and high-energy density capacitors.

This nanofilm developed by the team – measuring just 20 nanometers or less than one thousandth the thickness of a hair strand - is made from the ultra-high-molecular-weight polyethylene (UHMWPE) – a light-weight material used in bullet-proof vest. It was very difficult to reduce UHMWPE to nanoscale as the powder-like material breaks at a certain level under the conventional methodology which stretches it in opposite directions to change the intrinsic orientation of the disordered and entangled polymeric chain.

But Prof. Gao found a way to detangle the polymer chains. Similar to applying conditioner to smoothen the hair, Prof Gao’s team put UHMWPE into a lubricant and transform the material into a gel form, successfully enhancing its drawability while preventing the polymer chains from knotting. The team is thus able to rearrange the polymer chains into a topologically triangulated stable structure – a structure where some of the strongest material built upon.

Prof. Gao’s PhD student GU Qiao as well as CHEUNG Shu Kwan and Walter LEE from Design and Manufacturing Services Facility of HKUST have helped designing the transparent face mask.

1Stronger in terms of specific strength. While strength is commonly known as the amount of force a material could bear per unit area, specific strength is another concept which takes density into account. For example, steel and titanium can hold the same amount of force in the same area but titanium has higher specific strength as it is lighter than steel. Specific strength is especially important in the field of aerospace technology, as lightweight but robust mechanics are necessary for making aircrafts.

2Sodium Chloride Aerosol Challenge (NaCl) is a respirator prequalification test adopted by The National Institute for Occupational Safety and Health (NIOSH) to evaluate particle penetration and air flow resistance properties of a variety of filtration materials. This testing method is much stricter than U.S. Food and Drug Administration (FDA) approved surgical mask testing method.

About The Hong Kong University of Science and Technology

The Hong Kong University of Science and Technology (HKUST) (https://hkust.edu.hk/) is a world-class research intensive university that focuses on science, technology and business as well as humanities and social science. HKUST offers an international campus, and a holistic and interdisciplinary pedagogy to nurture well-rounded graduates with global vision, a strong entrepreneurial spirit and innovative thinking. HKUST attained the highest proportion of internationally excellent research work in the Research Assessment Exercise 2014 of Hong Kong’s University Grants Committee, and is ranked as the world’s best young university in Times Higher Education’s Young University Rankings 2020. Its graduates were ranked 26th worldwide and among the best from universities from Asia in Global University Employability Survey 2020.

For media enquiries, please contact:

Anita Lam

Tel: 2358 6313

Email: anitalam@ust.hk

Lindy Wong

Tel: 2358 6306 / 5190 7882

Email: lindywong@ust.hk