HKUST Researchers Pioneers Technique to Self-assemble High-performance Biomolecular Films

A research team led by The Hong Kong University of Science and Technology (HKUST) has developed a novel technique to self-assemble a thin layer of amino acids with ordered orientation over a large area that demonstrates high piezoelectric strength, making the manufacturing of biocompatible and biodegradable medical microdevices, such as pacemaker and implantable biosensor, in the near future possible.

The generation of bioelectricity from the piezoelectric effect – reversible conversion between mechanical and electrical energies – has physiological significance in living systems. Piezoelectric charges generated by the human tibia during walking boost bone remodeling and growth. Also, piezoelectric potential in the lungs generated during respiration could assist in binding oxygen to hemoglobin.

Currently, most of the piezoelectric materials are rigid, brittle and some of them even contain toxic materials like lead and quartz, making them unsuitable for implantation in the human body. Piezoelectric biomaterials such as amino acids are promising alternatives since they naturally exhibit biocompatibility, reliability, and sustainability. However, manipulating biomolecules at scale with an aligned orientation for functioning correctly has been proven difficult and remained an international academic challenge for 80 years.

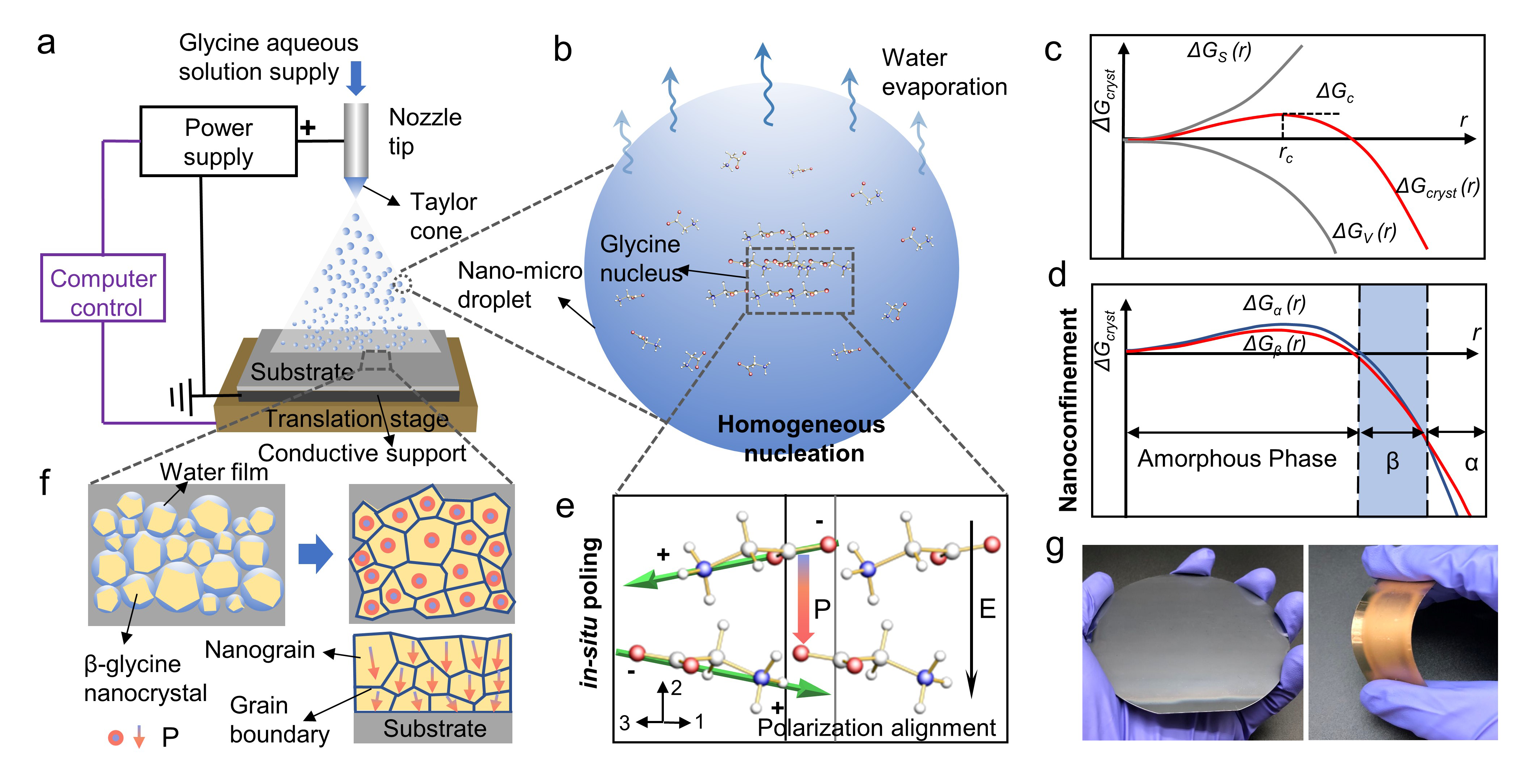

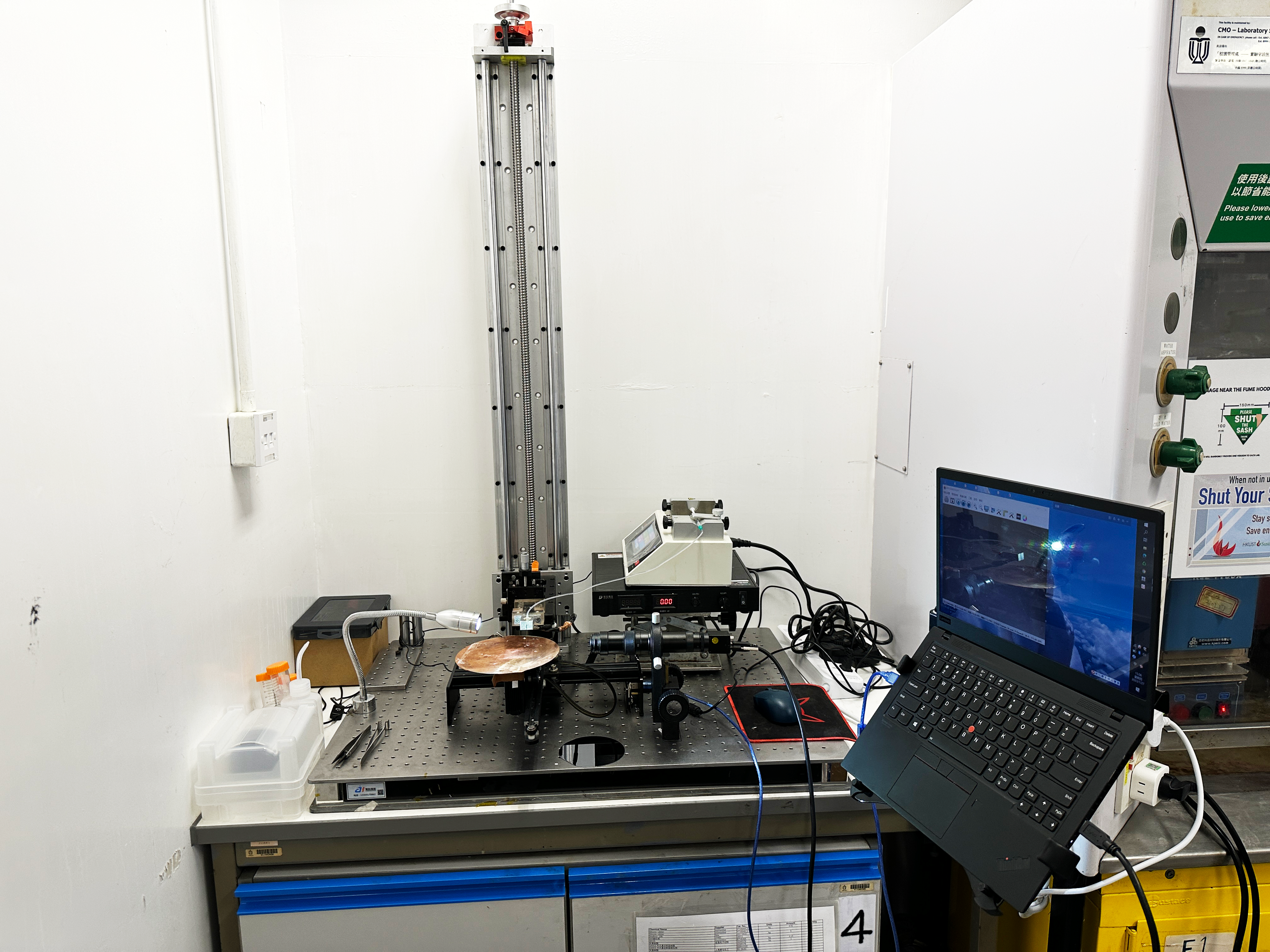

Addressing the long-standing challenge, a team led by Prof. Zhengbao YANG, Associate Professor in the Department of Mechanical and Aerospace Engineering at HKUST, recently developed an active self-assembly strategy to tailor piezoelectric biomaterial thin films via synergistic nanoconfinement and in-situ poling (see Figure). It enables biomolecules to self-assemble over a very large area with the same orientation. More importantly, based on this novel technique, the team found that films of a kind of amino acid, β-glycine, exhibit an enhanced piezoelectric strain coefficient of 11.2pmV−1, which is the highest compared to the other biomolecular films.

Their self-assembled piezoelectric biomolecular films are capable of producing electrical signals from mechanical stress produced by muscle stretching, breathing, blood flow and small body movements. With no batteries required, they will simply dissolve in the body when their mission is complete.

Prof. Yang said, “Our study shows uniformly high piezoelectric response and excellent thermostability across the entire β-glycine films. The excellent output performance, natural biocompatibility, and biodegradability of the β-glycine nanocrystalline films are of practical implications for high-performing transient biological electromechanical applications, such as implantable biosensor, wireless charging power supply for bioresorbable electronics, smart chip and other biomedical engineering purposes.”

The team will continue to examine ways in improving the film’s flexibility to match biological tissues, and achieving low-cost mass production of the bioresorbable piezoelectric films. They are also looking to conduct experiments in animals, to demonstrate biomedical applications in vivo.

This study is a collaborative work with City University of Hong Kong and University of Wollongong in Australia. The research findings were recently published in Nature Communications.