HKUST Engineering Researchers Develop Eco-Friendly Cooling Device with Record-Breaking Efficiency

Researchers at the School of Engineering of the Hong Kong University of Science and Technology (HKUST) have developed an eco-friendly refrigeration device with record-breaking cooling performance in the world, setting to transform industries reliant on cooling and reduce global energy use. With a boost in efficiency of over 48%, the new elastocaloric cooling technology opens a promising avenue for accelerating the commercialization of this disruptive technology and addressing the environmental challenges associated with traditional cooling systems.

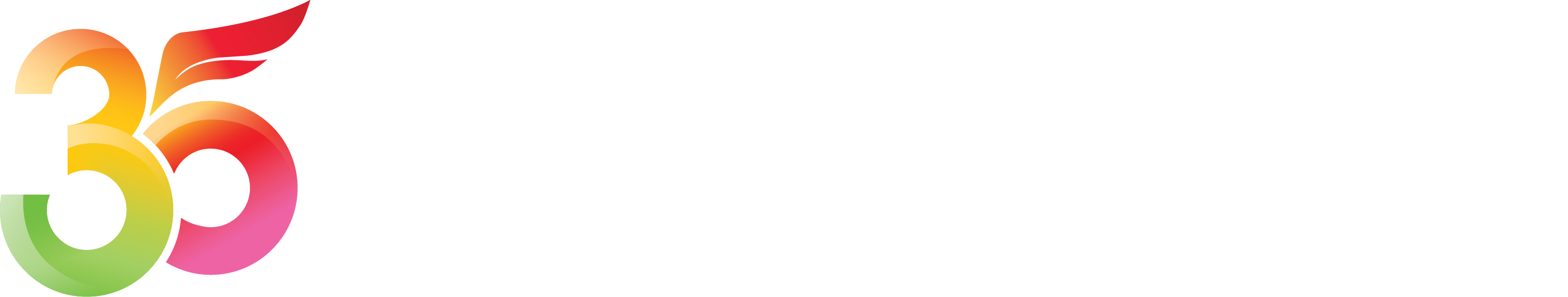

Traditional vapor compression refrigeration technology relies on refrigerants of high global warming potential. Solid-state elastocaloric refrigeration based on latent heat in the cyclic phase transition of shape memory alloys (SMAs) provides an environmentally friendly alternative, with its characteristics of greenhouse gas-free, 100% recyclable and energy-efficient SMA refrigerants. But the relatively small temperature lift between 20 and 50 K, which is a critical performance indicator of the cooling device’s ability to transfer heat from a low-temperature source to a high-temperature sink, has hindered the commercialization of this emerging technology.

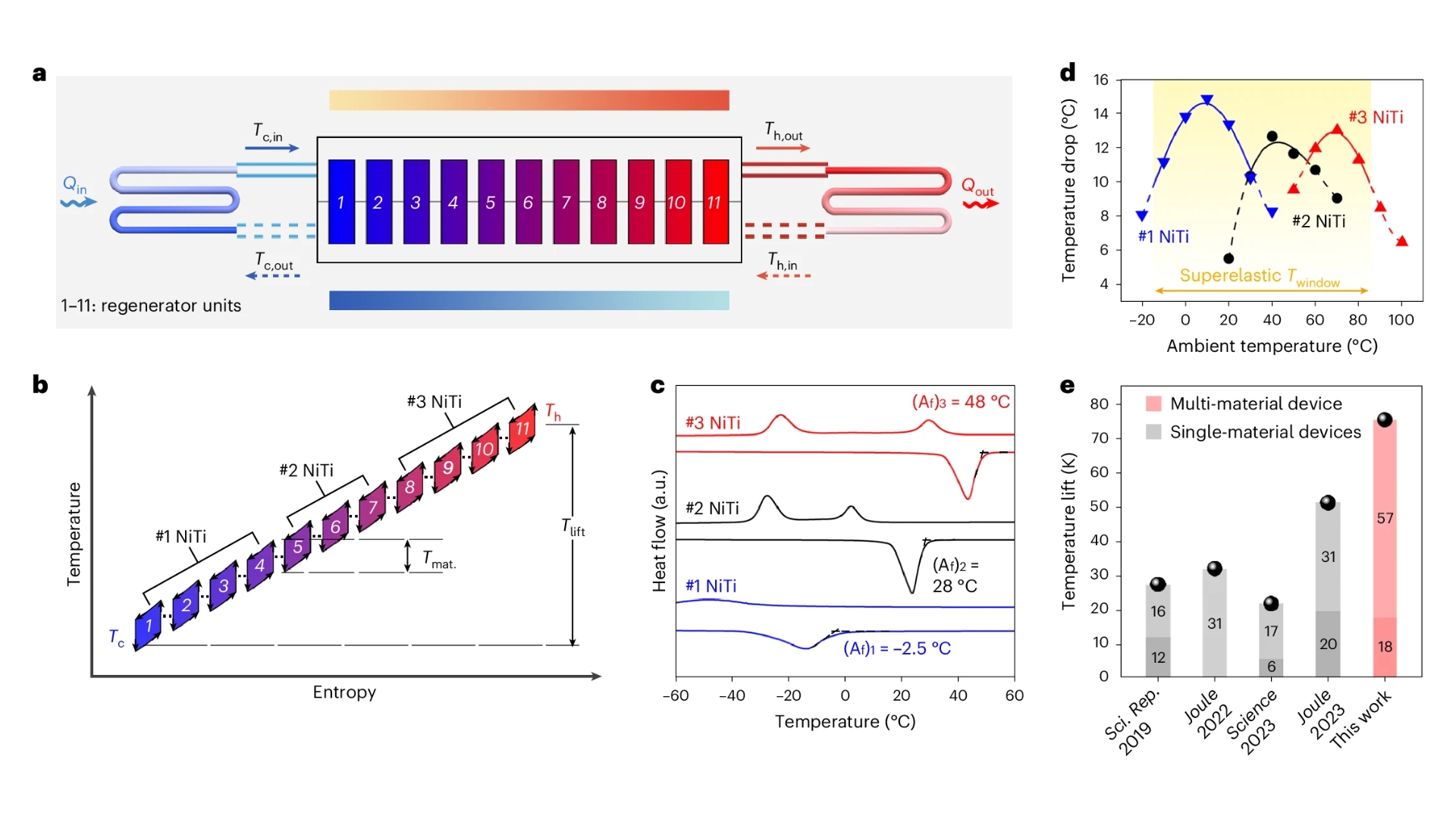

To overcome the challenge, the research team led by Prof. SUN Qingping and Prof. YAO Shuhuai from the Department of Mechanical and Aerospace Engineering has developed a multi-material cascading elastocaloric cooling device made of nickel-titanium (NiTi) shape memory alloys and broke the world record in its cooling performance.

They selected three NiTi alloys with different phase transition temperatures to operate at the cold end, intermediate end, and hot end, respectively. By matching the working temperatures of each unit with the corresponding phase transition temperatures, the overall device’s superelastic temperature window was expanded to over 100 K and each NiTi unit operated within its optimal temperature range, significantly enhancing the cooling efficiency. The built multi-material cascading elastocaloric cooling device achieved a temperature lift of 75 K on the water side, surpassing the previous world record of 50.6 K. Their research breakthrough, titled “A Multi-Material Cascade Elastocaloric Cooling Device for Large Temperature Lift”, was recently published in Nature Energy, a top journal in the field.

Building on the success in developing elastocaloric cooling materials and architectures with many patents and papers published in leading journals, the research team plans to further develop high-performance shape memory alloys and devices for sub-zero elastocaloric cooling and high-temperature heat pumping applications. They will continue to optimize material properties and develop high-energy efficient refrigeration systems to drive the commercialization of this innovative technology.

Space cooling and heating account for 20% of the world’s total electricity consumption and, according to industry estimates, are projected to become the second-largest source of global electricity demand by 2050.

“In the future, with the continuous advancement of materials science and mechanical engineering, we are confident that elastocaloric refrigeration can provide next-generation green and energy-efficient cooling and heating solutions to feed the huge worldwide refrigeration market, addressing the urgent task of decarbonization and global warming mitigation,” Prof. Sun said.

The research work was conducted by Prof. Sun and Prof. Yao (both corresponding authors), Postdoctoral Research Associate and PhD graduate Dr. ZHOU Guoan (first author), PhD student LI Zexi, PhD graduates ZHU Yuxiang and HUA Peng, as well as a collaborator from Wuhan University.