From Beam to Battery: HKUST’s Single-Step Laser Printing Supercharges High-Performance Lithium-Sulfur Batteries

A research team led by Prof. Mitch LI Guijun, Assistant Professor from the Division of Integrative Systems and Design at the Hong Kong University of Science and Technology (HKUST), has developed an innovative single-step laser printing technique to accelerate the manufacturing of lithium-sulfur batteries. Integrating the commonly time-consuming active materials synthesis and cathode preparation in a nanosecond-scale laser-induced conversion process, this technique is set to revolutionize the future industrial production of printable electrochemical energy storage devices. The findings of this study were recently published in the top journal Nature Communications.

Lithium-sulfur batteries are expected to supersede existing lithium-ion batteries due to sulfur cathodes' high theoretical energy density. To ensure the rapid conversion of sulfur species, these cathodes are typically composed of active materials, host materials (or catalysts), and conductive materials. However, the fabrication of host materials and preparation of sulfur cathodes often involve complicated, multistep, and labor-intensive processes that require varying temperatures and conditions, raising concerns about efficiency and cost in industrial production.

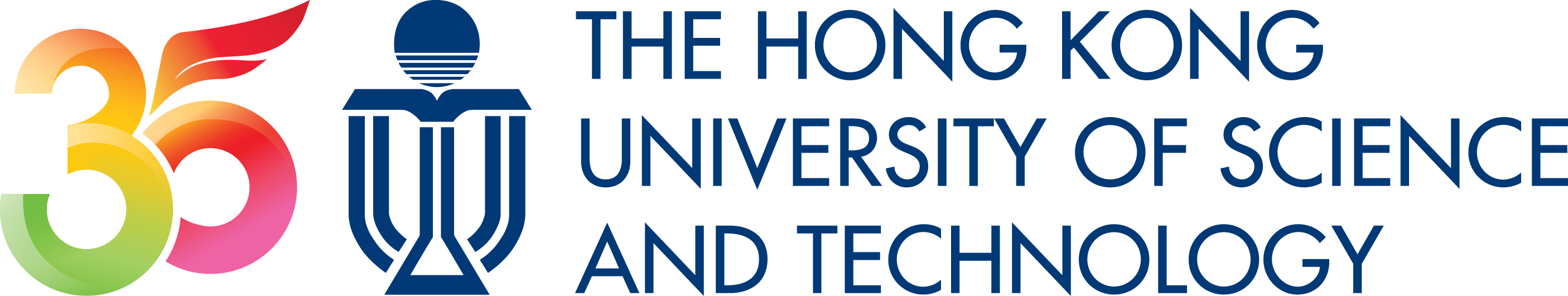

To overcome these challenges, Prof. Li’s team developed a novel single-step laser printing technique for the rapid manufacturing of integrated sulfur cathodes. During this high-throughput laser-pulse irradiation process, the precursor donor is activated, producing jetting particles that include in-situ synthesized halloysite-based hybrid nanotubes (host material), sulfur species (active material), and glucose-derived porous carbon (conductive component). The mixture is printed onto a carbon fabric acceptor, forming an integrated sulfur cathode. Notably, the laser-printed sulfur cathodes demonstrate outstanding performance in both coin and pouch lithium-sulfur cells.

“Traditional manufacturing processes of a cathode/anode in ion battery usually contain the synthesis of active materials (sometimes combined with host material/ catalyst), the preparation of mixture slurry, and the assembly of cathode/anode. Prof. Li explained, “These steps are usually carried out separately under different temperatures and conditions because the materials behave differently. As a result, the whole process can take tens of hours or even several days.”

Prof. Li said, “Our newly developed laser-induced conversion technology offers a way to combine these processes into a single step at nanosecond speeds. The printing speed can achieve about 2 cm2/minute using only a single beam laser. A 75 × 45 mm2 sulfur cathode can be printed within 20 minutes and supply power for a small screen for several hours when assembled into a lithium-sulfur pouch cell.”

Dr. YANG Rongliang, the first author of this work and former postdoctoral fellow at HKUST, added, “These intriguing findings generated from our study on laser-material interaction. The laser-induced conversion process can be characterized as an ultra-concentrated thermal phenomenon. The irradiated materials undergo a complex transient heating and cooling process, with theoretical transient temperatures reaching up to thousands of degrees Kelvin. The precursor materials decompose, and the decomposed particles recombine to form new materials. This ultra-concentrated thermal process not only enables the formation and combination of materials with different natures, but also drives the concomitant micro-explosions that facilitate the jetting and transferring of forming particles.”

Note: Dr. YANG Rongliang, a former postdoctoral fellow from the Division of Integrative Systems and Design at HKUST, is the first author, and Prof. Mitch LI Guijun at HKUST is the corresponding author. The research also received substantial support from Prof. TANG Aidong from Central South University China and the China University of Geosciences, and Senior Engineer LI Tianbao and Senior Engineer TU Feiyue from Changsha Research Institute of Mining and Metallurgy Co. LTD. The research is funded by Hong Kong Innovation Technology Commission (ITC) under project number MHP/060/21.